The manufacturing sector has faced a barrage of challenges over the years. Heightened volatility is the new normal, straining traditional methods of production. The ability to quickly assess risks and opportunities and respond the right way can make all the difference to success or failure. And digital tool is always the key.

Big firms with deep pockets can respond by investing in the latest and greatest data-driven solutions and automation technologies to integrate into their manufacturing processes. This fosters information gathering, faster decision-making, streamlined operations, optimal supplier relations, and more efficient inventory management.

SMEs, often constrained by limited resources, can have a harder time of it. They require easier-to-implement, cost-effective digital tools that can lower the barriers to investment in tech-driven solutions.

That’s where WeCom comes in. The open-access digital platform for enterprise can help any business, including SMEs and entrepreneurs, achieve this in three ways:

- Boosting Collaboration. WeCom facilitates teamwork and partnerships by connecting over 12 million enterprises and organizations in China. It allows them to share customer insights among members and streamline workflows.

- Expanding Reach. Businesses have potential access to 1.3 billion Weixin and WeChat users for direct customer engagement. Quick service and data insights fuel growth and optimizes manufacturing.

- Making the Office More Efficient. Features like document sharing and scheduling enhance internal communication and lead to a more efficient office, whether working in-person or remote.

How Three SMEs Successfully Used WeCom

A pipeline manufacturer, a USB-C port maker, and a phone case manufacturer. These three SMEs and entrepreneurs have something in common: They harnessed digital tools like WeCom to unlock additional business potential, reduce costs, expand their customer base, and create sustained growth.

1. Lao Deng: A determined newcomer breaks into a competitive industry

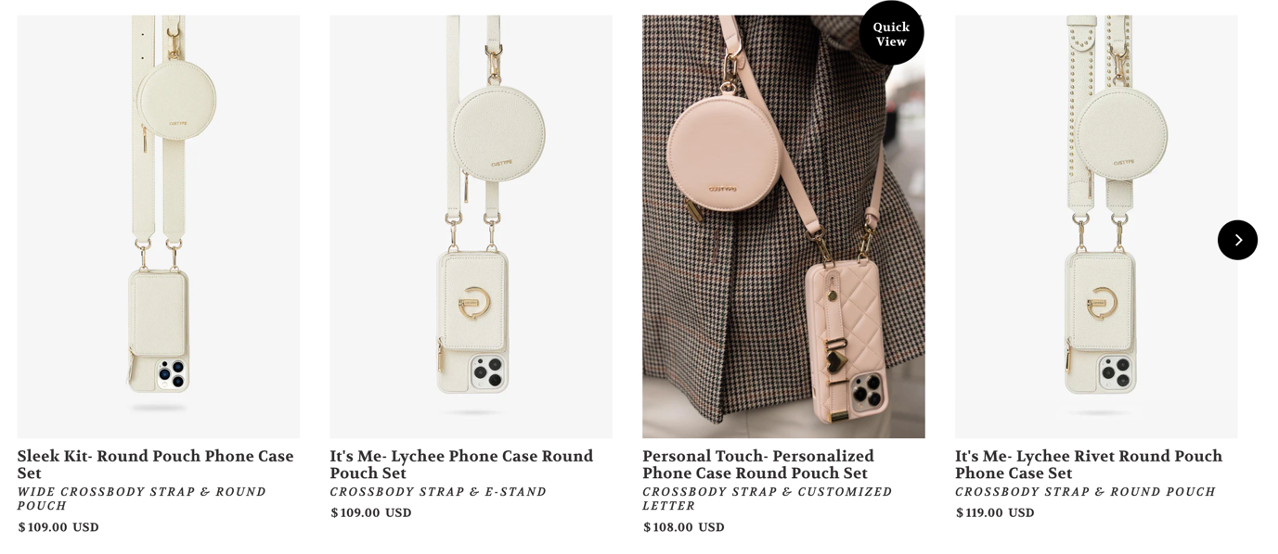

Lao Deng is the owner of a creative factory with only 60 employees, specialising in the design, manufacturing and foreign trade of phone cases. He started producing Nokia phone cases in early 2000s, which were popular in Europe and America.

As an entrepreneur with years of experience in the foreign trade industry, he felt that domestic brands faced significant challenges in a highly competitive market. Continuous high-frequency product updates could greatly boost sales. However, this requires a highly efficient supply chain collaboration. He needed an innovative approach to coordinate with suppliers more effectively.

Success story: With the help of partners, Lao Deng used WeCom to connect with his network of suppliers. This enabled automated order placement and tracking, and reduced manual data entry and errors. Group chats facilitated communication among design teams, procurement, and suppliers, ensuring that new product development was closely coordinated. Lao Deng’s use of WeCom allowed him to receive real-time notifications, ensuring timely responses and faster product launches.

Outcome: Lao Deng’s business turned into steady growth, showcasing how WeCom empowers small businesses to flourish even with limited resources.

2. Yttrium Rainbow Precision: Digitalization doesn’t have to be expensive to be effective

Yttrium Rainbow Precision, a small company with 45 employees specializing in USB-C port manufacturing, faced industry challenges such as pricing pressures and demanding quality standards.

Success story: Yttrium Rainbow Precision adopted WeCom to create customized workflow processes for different departments, enhancing productivity. Processes such as order signing and quality inspections can be directed via WeCom to designated departments and persons in charge to complete the approval process, no longer relying on paper archives. Moreover, WeCom’s collaboration tools enabled easy communication between remote teams, ensuring that changes and updates were promptly shared and implemented.

Outcome: Using a digital tool costing just around 8,000 RMB (USD1,000) a year led to improved efficiency, reduced workloads, and a rise in sales, demonstrating that digitalization doesn’t have to be expensive to be effective.

A statistical dashboard of the production process, powered by WeCom.

3. Ri Feng Group: Simplifying production planning and giving service engineers the tools to succeed

Ri Feng Group, a company in the pipeline industry with operations spread across eight production plants, nine domestic subsidiaries, and over 1,000 sales agents, knew they had to go digital for future success.

Success story: Ri Feng Group established a comprehensive digital solution via WeCom. The company integrated the platform with their ERP (Enterprise Resource Planning) system, which enabled them to synchronize data in real-time across production plants and domestic subsidiaries. This allowed for better production planning, inventory management, and order processing. In addition, the interconnectivity between WeCom and Weixin enables the service engineers of Ri Feng Group to join group chats conveniently, receive regular online training, product feedback and quickly resolve unexpected issues encountered during the service process.

Outcome: Ri Feng Group saw sales growth, improved communication and collaboration across their operations.

The above three case studies spotlight the power of digitalization and effective communication in manufacturing, sales and inventory management. By embracing cost-effective solutions like WeCom, SME manufacturers can enhance flexibility, responsiveness, and resilience, enabling them to thrive long term in a dynamic landscape.